- Email : kinsda@kinsda.cn

- Phone : +86 755 61808681

- Fax : +86 755 61808682

- Address : No.18, High-tech Industry Park, Longgang District, Shenzhen, China

-

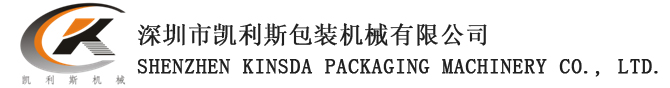

KGJ High Speed Automatic Rotary-Blade Paper Sheeter

-

Product Description

Development Process brief:

With introduction of foreign advanced technology and processes, according to the feedback information from the users and the features of the roll paper sheeting industry, we developed GDJ series high speed Automatic Rotary-blade paper sheeting machine, this machine has many merits compared with similar products, with advanced development concept and perfect designed structure, it characterize by high degree automation, very stable performance, easy to operation, elegant product appearance. To guarantee the machine quality and service life, it adopts high electric components, such as brand SIMENSE, OMRON, YASKAWA, SCHEIDER. Also with lots of optimization and upgrading, like add the dual touch-screen displays, and upgrade the electric apparatus control system and computer programs, which allow the machine work more stably and accurately. It is a deal equipment for roll paper sheeting industry.

Application :

Applicable to a variety of reel of papers (Ivory board, Grey board, White board Coated board, Kraft paper etc.) Widely used in all kinds of paper mills, printing house, carton packaging plant, paper distributor, paper processing.

Main tech specification:

Model

KGJ1700

KGJ1400

Cutting blade width

1750mm

1450mm

Roller width

1750mm

1450mm

Max. Unwinding Width

1700mm

1400mm

Sheet Length Range

450-1700mm

450-1400mm

Max. Speed

300m/min

300m/min

Max. Unwinding Dia

1500mm

1500mm

Paper Thickness

50~550 g/m2

50~550 g/m2

Cut-off Accuracy

±0.3 mm

±0.3 mm

Pile Height

1300mm

1300mm

Total power

30kw

28kw

Total weight

14T

13T

Dimension

12500x3500x2400mm

12500x3200x2400mm

Electrical components configuration list:

Description Model Brand from

1. Magnetic valve Taiwan

2. Motor 2.2kw Taiwan

3. Pneumatic-current converter SJDH Japan/Italy

4. Servo motor SMGD11KW Taiwan

5. Servo drivers SMGH 11KW Taiwan

6. Variable frequency motor 7.5kw Shanghai

7. 3-phase motor 1.5kw Shanghai

8. 3-phase motor 0.55kw Shanghai

9. Encoder 2500RP Japan

10. Frequency converter 1000-7.5kw Japan

11. Frequency converter 1000-1.5kw Japan

12. Resistance 1500w Shanghai

13. Transformer 20KVA Guangdong

14. Human-computer interface 7 inch Taiwan

15. CMOD EM 22 6 S700-2 00 Germany

16. CMOD EM 232 Germany

17. CMOD EM233 Germany

18. Low-voltage apparatus Taiwan

19. Pneumatic components Taiwan

20. Main bearings Japan

Main Unit:

◆ Hydraulic shaftless mill roll stand

1. Load-bearing type double position hydraulic shaftless mill roll stand, hydraulic system: move upward overall, move downward overall, move left overall, move right overall, clamp around the middle overall, loosen both sizes, 6 movements are done accurately

◆ Machine Main part

1. Machine wallboard are made of 45# steel, processed in advanced high- precision machining center.

2. Hob cutter body use high –grade alloy steel

3. Lower cutter are cast from high-strength material, with high intensity, stability and non-deformation in the long-term use

4. With trimming cutters

5. Correction mechanism takes the simple but efficient pneumatic locking mechanism, manual adjustment device.

6. Upper and lower cutters adopt special paper cutters made of high grade alloy steel.

7. The feeding part: upper roller use high-elasticity and wearable rubber, lower roller use high-strength seamless steel tube, the control device takes low-friction cylinder pneumatic control.

8. Paper anti-curve device: according to the curvature of the paper core, multi-angle adjust to ensure the paper flat and smooth.

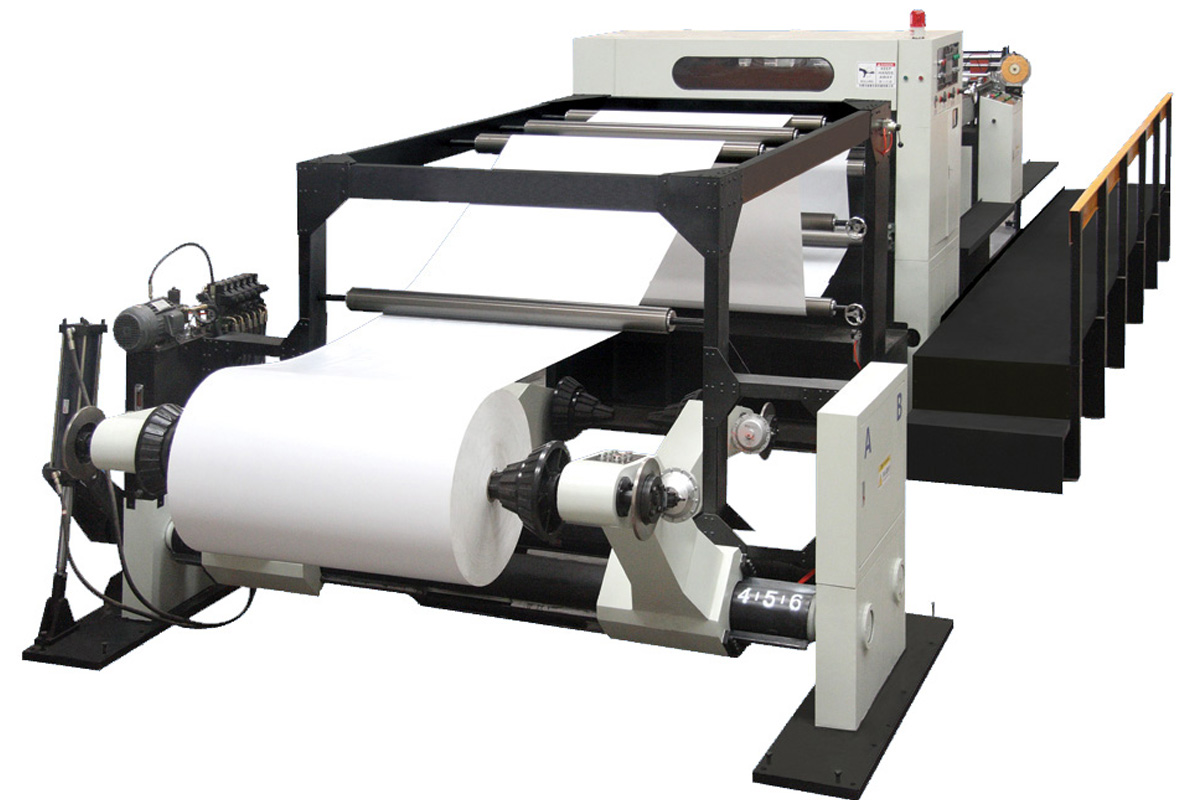

◆ Conveying part

1. the conveying unit is consist of 2 parts : front part and latter part. The front conveying unit is synchronous control with the main machine; the latter conveying unit takes step-less frequency conversion timing, realize separate control or linkage control, can deliver the paper sheets in imbricate state.

2. Configure dedicated high-speed anti-scratch pressure rollers to ensure non-scratch on the surface of the paper during the high-speed operation.

3. Static elimination device avoid paper electrostatic problem which may affect the paper delivering and stacking.

4. Add the dust-removal and paper scrap dealing device to make the paper sheets clean and tidy, and in good condition for the later printing.

◆ Stacking unit.

1. Four sizes automatic positioning, left-right tiding device apply the high-frequency electric motor vibration, the front apply mechanical arm to flap tidy, the back baffle is adjustable, which can make the paper pile perfectly neat.

2. Receiving station is consist of electric motor and deceleration mechanism. Cable reel takes the automatic wiring mechanism, to make the wirerope neat and tidy.

◆ Electrical control part

Siemens PLC control, human-computer interface control system, parameter setting, JOG pattern, counting function, emergency warning function. Counting down function, meter counting function, automatic put function etc.

Comnon facility condition on site

1. Air compressor: 82psi(3KW 0.8PA)

2. Alternating current: three phase four wire system 380V 50HZ

3. Wire cable:16mm2 (three phase type)

4. The ground load-bearing:1500kg/m2

5. Equipment operation environment temperature 5 to 40 degree centigrade