- Email : kinsda@kinsda.cn

- Phone : +86 755 61808681

- Fax : +86 755 61808682

- Address : No.18, High-tech Industry Park, Longgang District, Shenzhen, China

-

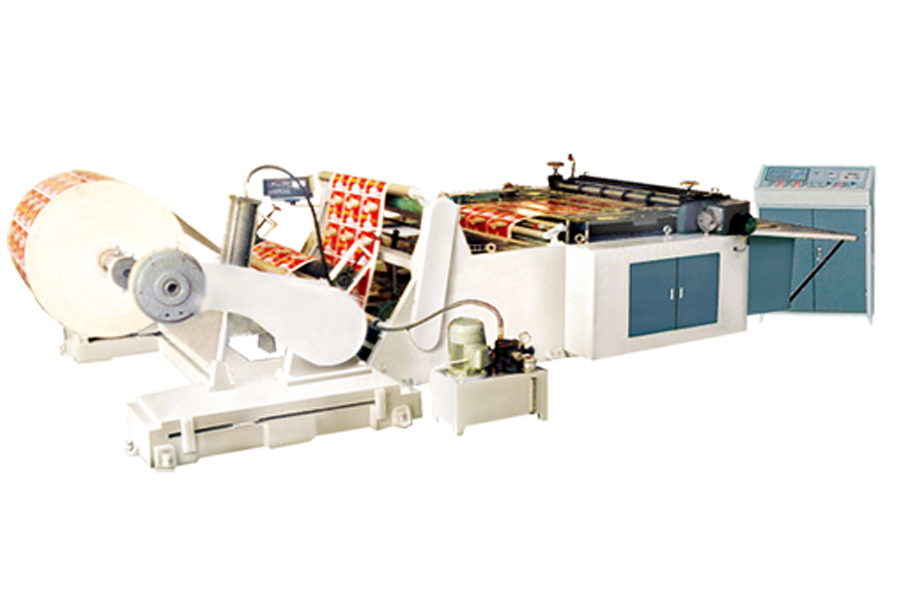

KHB1300 Automatic high precision paper/PP sheeter

-

Product Description

Feature:

KHB1300 is designed for low budget customer, yet it is made on a high standard level. It adopts tong-torque stepper system, hydraulic lifting feeding, magnetic powder brake system, computer control to make sure the high precision cutting (±0.15mm),and use high quality electrical components(EURA variable frequency speed regulation system, SCHNEIDER low voltage apparatus). It is a well design, mature equipments with compact strong structure, very perfect equipments for the middle & small enterprise who pursue the high precision cutting

Application :

Applicable to a variety of roll material of BOPP/PP/PC film & papers (Ivory board, Grey board, White board Coated board, Kraft paper etc.) Widely used in all kinds of paper mills, printing house, carton packaging plant, paper distributor, paper processing.

Main tech specification :

Model

KHB1300

Cutting blade width

1300mm

Roller width

1300mm

Max. Unwinding Width

1300mm

Min. Unwinding Width

300mm

Sheet Length Range

5-2000mm

Max. Speed

60m/min

Max. Unwinding Dia

1500mm

Paper Thickness

50~550 g/m2

Cut-off Accuracy

±0.15 mm

Total power

7kw

Total weight

7.5 T

Dimension

6000x2000x1300mm

Main Unit:

◆ Hydraulic reel stand

Load-bearing type single position hydraulic mill roll stand, with 1 set of The hydraulic motor pump, equipped with magnetic powder brake 200NM and digital display type tension control

◆ Machine main part

1. Machine wallboard is made of high quality box iron by advanced welding process technology

2. Lower cutter are cast from high-strength material, with high intensity, stability and non-deformation in the long-term use.

3. Upper and lower cutters adopt special paper cutters forged from high strength steel W18Cr4V, sharply and accurately to cut, durable to use.

4. Traction and transmission mechanism: adopt 52NM stepper servo drive system, driven by circular gear shape synchronous wheels, it characterize by high precision, high strength, low noise

5. Control model: high performance computer control, human-computer centralized operation.

6. Pre-delivery part: upper roller use high-elasticity and wearable rubber, lower roller use high-strength seamless steel tube, driven by 3phase AC motor, transmitted by belts, stepless frequency conversion

7. 3phase AC motor transmit to reducer, then transmit to eccentric cam, then drive the cutter body up and down cutting movement, with stepless frequency conversion

◆ Electrical apparatus control system

1. PLC control, human-computer interface control system, parameter setting, JOG pattern, counting function, emergency warning function. Counting down function, meter counting function, automatic put function etc.

2. adopt stepless frequency timing control

Electrical components configuration list:

Description

Model

QTY(set/pcs)

Brand from

Human- machine interface

single-chip microcomputer

1

Taiwan

Computer control system

PC

1

Taiwan

Motor

2.2kw

1

Shanghai

Motor

1.5kw

2

Shanghai

Stepper servo motor

130wt

1

Taiwan

Stepper driver

130ET

1

Taiwan

Gear reducer

WPA100-1/15

1

Guangdong

Frequency converter

F1000-2.2KW

2

Shanghai

Frequency converter

F1000-1.5KW

2

Shanghai

Low voltage apparatus

1

Schneider

Magnetic powder brake syestem

200NM

1

Taiwan

Digital display type tension control

4A

1

Guangdong

3inch

1

Shanghai