- Email : kinsda@kinsda.cn

- Phone : +86 755 61808681

- Fax : +86 755 61808682

- Address : No.18, High-tech Industry Park, Longgang District, Shenzhen, China

-

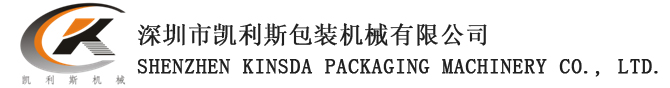

KHA1600 Automatic High precision Rotary-blade sheeter

-

Product Description

Development Process Brief:

KHQ series rotary-blade sheeting machine is designed with high precision (±0.15mm), It is mainly characterized by a large number of applications of foreign brands of electrical control (such as Japan: Yaskawa; Japan: Omron; Germany: Siemens; France: Schneider; Taiwan: Delta etc.). Good machine structure, use high-precision machining center to process the main mechanical components, Advanced, processing technology and strict testing means and technical requirements to ensure the accuracy of the various parts. Thus ensuring the stability and performance of the machine cutting precision. It is a very mature product used for years in the sheeting industry, receiving high praise for its high precision cutting, stable running, which are highly welcomed by the middle/small enterprise.

Application

Applicable to a variety of reel of papers (120-500gsm Ivory board, Grey board, White board Coated board, Kraft paper etc.) Widely used in all kinds of paper mills, printing house, carton packaging plant, paper distributor, paper processing.

Main tech specification:

Model

KHA1600

Cutting blade width

1650mm

Roller width

1650mm

Max. Unwinding Width

1600mm

Sheet Length Range

500-1600mm

Max. Speed

120m/min

Max. Unwinding Dia

1500mm

Paper Thickness

120~500 g/m2

Cut-off Accuracy

±0.15 mm

Pile Height

1200mm

Total power

11kw

Total weight

7T

Dimension

9000x3200x2200mm

Electrical components configuration list:

1. Description Model Brand from

2. Human-computer interface 5.7inch Taiwan

3. Computer control system Japan

4. Electromagnetic hydraulic valve Taiwan

5. Pneumatic electromagnetic valve Taiwan

6. Motor 1.5KW Taiwan

7. Motor 1.5KW-6 Taiwan

8. Motor 2.2KW Taiwan

9. Motor 0.75KW Taiwan

10. Motor 0.55KW-6 Taiwan

11. Motor 1.5KW-4 Taiwan

12. Servo motor SMGD4.4KW Japan

13. Servo drivers SMGD4.4KW Japan

14. Resistance 1200W France

15. Reducer WPA 100 1/15 Shanghai

16. Reducer WPA 100 1/60 Shanghai

17. Frequency converter F1000—1.5KW Germany

18. Frequency converter F1000—2.2KW Germany

19. Frequency converter F1000—0.75KW Germany

20. Low-voltage apparatus Taiwan

21. Pneumatic components Taiwan

22. Main bearings Japan

Main Unit:

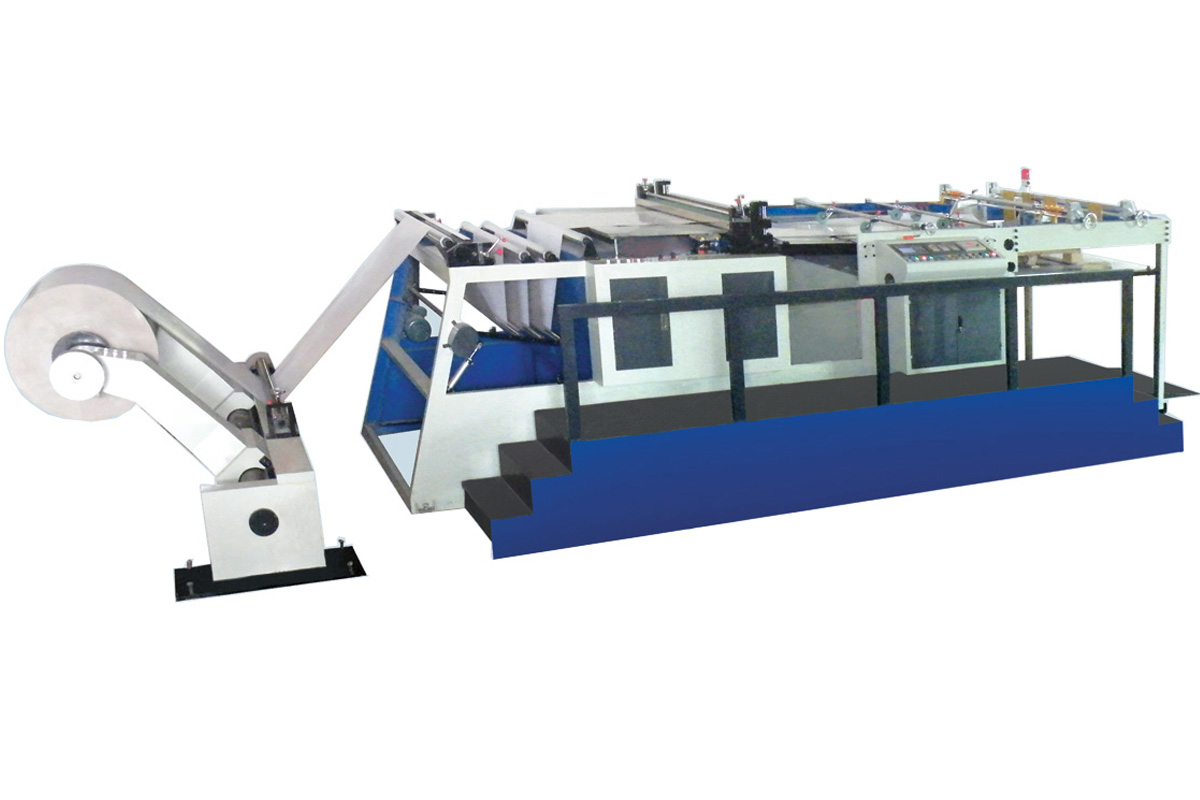

◆ Hydraulic shaftless mill roll stand

1. load-bearing type single position hydraulic mill roll stand, main center shaft use 45# steel, dia 180 seamless steel tube, right-left steel arm adopt combined type.

2. move upward overall, move downward overall, move left overall, move right overall, clamp around the middle overall, loosen both sizes, 6 movements are done accurately. right-left movement configure heavy-duty type SC80X700 oil cylinder, up-down movement configure heavy-duty type SC125X350 oil cylinder hydraulic components are from Taiwan famous brand.

3. Tension control: pneumatic type disc brake, tension of manual control.

◆ Machine main part

1. Machine wallboard is made of high quality box iron by advanced welding process technology.

2. Lower cutter are cast from high-strength material, with high intensity, stability and non-deformation in the long-term use

3. Upper and lower cutters adopt special paper cutters forged from high strength steel W18Cr4V, sharply and accurately to cut, durable to use.

4. Traction and transmission mechanism:: with 4.4kw Japan YASKAWA servo drive system, driven by circular gear shape synchronous wheels, it characterize by high precision, high strength, low noise.

5. Control model: high performance computer control, human-computer centralized operation

6. Pre-delivery part: upper roller use high-elasticity and wearable rubber, lower roller use high-strength seamless steel tube, driven by 3phase AC motor, transmitted by belts, stepless frequency conversion.

7. 3phase AC motor transmit to reducer, then transmit to eccentric cam, then drive the cutter body up and down cutting movement, with stepless frequency conversion.

◆ Automatic stacking unit

1. delivery is consist of 2 sections, delivery speed can be adjusted automatic/by manual control so that can match the speed of main machine. It apply the stepless frequency conversion timing control.

2. delivery guide roller take high grade seamless steel tube, with hard chrome plating and correcting and drilling balance.

3. Four sizes automatic positioning, left-right tiding device apply the high-frequency electric motor vibration, the front apply mechanical arm to flap tidy, the back baffle is adjustable, which can make the paper pile perfectly neat.

4. Receiving station is consisted of electric motor and deceleration mechanism. Cable reel takes the automatic wiring mechanism, to make the wirerope neat and tidy.

◆ Electrical control part

1. Siemens PLC control, human-computer interface control system, parameter setting, JOG pattern, counting function, emergency warning function. Counting down function, meter counting function, automatic put function etc.

2. adopt stepless frequency timing control

Comnon facility condition on site

1. Air compressor: 82psi(3KW 0.8PA)

2. Alternating current: three phase four wire system 380V 50HZ

3. Wire cable:16mm2 (three phase type)

4. The ground load-bearing:1500kg/m2

5. Equipment operation environment temperature 5 to 40 degree centigrade