- Email : kinsda@kinsda.cn

- Phone : +86 755 61808681

- Fax : +86 755 61808682

- Address : No.18, High-tech Industry Park, Longgang District, Shenzhen, China

-

KFGM-650/800PC Automatic High-speed Folder Gluer

-

Product Description

Features:

The machine is designed for the production line of mid-sized and small-sized paper cartons. When the cardboard are indented, they will be automatically fed into machine, folded, glued, pressed, erected and ready for packing. The machine is suitable for producing Straight Line, Double sides, Crash lock and CD cases.

◆The machine is adopted with strengthened sing-side driving system for steady running and easy maintenance.

◆Equipped with inverter, efficient and strong motor controls the speed automatically, which is steady and power-saving.

◆It is adopted with screw rod adjusting in operation, easy and convenient.

◆Delivery is adopted with several original thickened high-quality belts cooperating with vibrating motor to ensure continuous, exact and automatic feeding.

◆High-quality transmission belt works up and down and reduces abrasion to the minimum.

◆It offers two groups of upper and lower gluing tanks, which can adjust automatically vertically and adopt tooth rod in adjusting horizontally, for easy operation.

◆It is adopted with touch screen, PLC controller, photoelectric counting, and automatic sheet kicker, which makes the machine function fully.

◆Conveying pressure table uses special materials to adjust pressure through air pressure, and it is equipped with sponge belt to ensure the perfect quality of the product.

◆It is equipped with high power servo controlling system to ensure quality.

◆The machine is available to standard folding boxes, double-sides boxes, and crash lock bottom boxes.

◆Cold & hot glue gun system as option. Machines can be designed for special boxes according to the requirements of the customers.

Configuration of the machine:

1、Mode → Strengthened single side

2、Primary motor →Siemens(Made in Germany)

3、Convey motor →ESPA(Made in Taiwan)

4、Conveyor belt →NITTA(Made in Japan)

5、Photoelectricity →SUNX (Made in Japan)

6、PLC controller →Panasonic (Made in Japan)

7、Frequency converter →Panasonic (Made in Japan)

8、Clutches →BEIYI(Made in Taiwan)

9、Electricity button →FUJI(Made in Japan)

10、Bearings →NSK(Japan), Harbin, Luoyang

11、Drive Bearings →MZD,NSK(Japan)

Machine Structure:

The machine has the following seven parts: Feeding unit, Pre-folding unit, Crash lock bottom unit, Gluing unit, Final folding unit, Trombone unit, and Conveying unit.

1. Feeding unit:Using non-stop bottom-delivery feeding type, thickened feeding belts cooperating with the vibration motor to ensure smooth feeding.12mmmetal plate moves horizontally to set the width, embossed momentum guide impeller used for guiding the paper-output belt. There are aluminum alloy blocking plates on both left and right sides, which can be adjusted left and right to suit the product style. It is also equipped with two paper-output knives, which are used to adjust the asymmetric length according to the practical samples. The strength of the vibrating motor is adjusted according to the in-out of the vibration shelf. The whole combined completes the rapid, continuous, and accurate automatic feeding, and the feeding distance can be adjusted with speed control.

2. Pre-folding unit: It can adopt two-plate style belts design according to the box type to make No.1 crease turns 180°, No.3 crease 135° and then unfold, which is convenient for opening the boxes when filling materials.

3. Crash lock bottom unit: All the pasting buckets can be installed and be removed. There are two upper gluing tanks on the left and right separately, and the same with the lower gluing tanks, which are chosen to be used according to the practical situation. The quantity of the gluing tank can be adjusted, stable and easy for maintenance. The thickness of the pasting wheel is4mm, and can also suit the specific requirement of the customer. The gluing tanks are made of sturdy and durable entirely copper-casted material. The crash lock bottom gluing is finished with four groups of crash lock bottom devices. Crash lock bottom action is stable & accurate, and the operation is fast & easy.

a) Gluing unit: Left & Right, Upper & Lower gluing tanks can be adjusted separately. The amount of the adhesive is stable, big volume and easy for maintenance.

b) Final folding unit: Long journey design to finish No. 2 crease turns 180°on both left and right, No.4 crease 180° to completely combine each other. The left and right guide wheels adjust according to the different position to make the folding more smoothly.

c) Trombone unit: The upper and lower transmission can adjust the length; adjust the system automatically as per the degree of the tight-loose state of the belts ; continuous and automatic collecting of boxes ensures the uniform transmission to the conveying unit; photoelectric counting, and automatic sheet kicker; equipped with pneumatic system and pressing transmission system.

d) Conveying unit: Equipped with independent imported belts, soft and moderate so that the finished products can not be damaged. The whole conveying unit can move front and back; even pressing and uniform delivery ensures the quality prefect. The conveying speed can be adjusted automatically according to the speed of the main machine cooperating with the photoelectric machine. Manual operation mode and speed is optional.

Main Specifications:

Model

KFGM-6500PC

KFGM-800PC

Materials to be processed

Card, corrugated(E,F,N flute)

Card, corrugated(E,F,N flute)

Thickness of the cardboard

200g~700g/㎡

200g~700g/㎡

Width of the carton

90mm~650mm

100mm~800mm

Type of glue

Resin emulsion(solute)

Resin emulsion(solute)

Max. Line speed

300m/min

300m/min

Total power

9 kw

9 kw

Dimensions(L*W*H)

11.6×1.50×1.45m

12.1×1.65×1.46m

Net weight

4.0 metric tons

4.5 metric tons

Carton size specifications:

Box style and size:

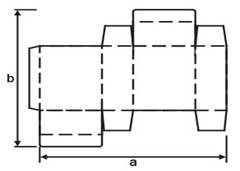

(1). One-side gluing:

KFGM-650PC

KFGM-800PC

a

90-650mm

100-800mm

b max.

700mm

700mm

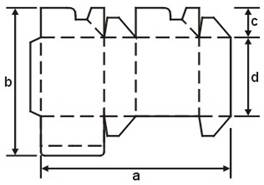

(2). Bottom gluing:

KFGM-650PC

KFGM-800PC

a

135-600mm

160-700mm

b max.

600mm

600mm

c

25-90mm

25-90mm

d min.

60mm

60mm

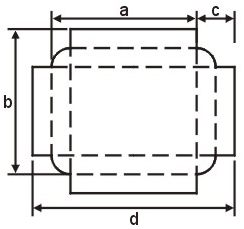

(3). Double-side gluing

KFGM-650PC

KFGM-800PC

a

80- 520mm

100-620mm

b

90~600mm

100-600mm

c

15-100mm

15-100mm

d

110~530 mm

190-630mm

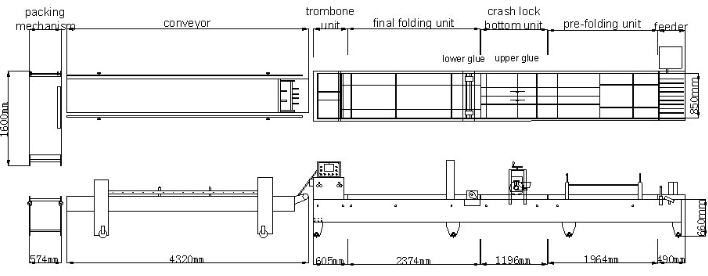

Floor plan:

Attachment:

1. The standard configuration of the machine is as following:

No.

Item

Spec.

Qty

Brand

1

Main machine

1*2

16mm national standard steel plate through heat treatment and controlled cooling process

2

Conveyor

1*2

16mm national standard steel through heat treatment and controlled cooling process

3

Main motor

4P/7.5KW

1 set

SIEMENS from Germany

4

Conveyor motor

1HP/0.75KW/1:30

1 set

electromagnetic governor motor ,ESPA from Taiwan

5

Inverter

7.5KW, VF100-0754

1 set

Panasonic(Japan)

6

PLC(controller)

FPX-C30RS

1 set

Panasonic(Japan)

7

Touch screen

1 set

WEINVIEW

8

Variable speed

transmission plate

AH-140-19

PH-155-18

1422V300

1 set

Beiyi (Taiwan )

9

Clutches

C-M40-R01-25

1 set

Beiyi (Taiwan )

10

Key switch

Fuji(Japan)

11

Wireless remote controller

8 keys

12

Feeding belt

NITTA (Japan)

13

Bearings

NSK, Luoyang, Harbin

14

Drive bearings

MZD, NSK(Japan)

15

Conveyor belt

Italy

16

chromium plated handle

Through hardening and tempering treatment (Taiwan)

17

Conveyor cylinder

TPM, Xingchen

18

Base unit belt

NITTA (Japan)

19

Timing Belt

Gates (US)

20

Hanging board

Aluminum profile through oxidation and sandblasting treatment

21

roller

Through external grinding, hardening and tempering, heating treatment

22

Gluing tank

Special high-precision copper casting and stainless steel disc technology portfolio

23

Grinding machine

Aluminum motor with diamond grinding

The above catalog is for reference only. They can be equipped as per the

customers’ requirement.

Accessories with the machine:

No.

Product name

Qty

KFGM-650/800PC

1

Vibration motor

1 set

√

2

Feeding knife

Main knife

2 pcs

√

3

Auxiliary knife

2 pcs

√

4

The 1st line folder

1 set

√

5

The 3rd line pre-folding

1 set

√

6

hook

4 pcs

√

7

Layer for crash lock bottom

2 pcs

√

8

Auxiliary button device

8 pcs

√

9

Support bridge

2 pcs

√

10

Pull hammer

1 pcs

√

11

Anti-crash wire

4 pcs

√

12

Screw rod crank

1 pcs

√

13

Rubber hammer

1 pcs

√

14

Grease gun

1 pcs

√

15

Wind gun gas pipe

1 set

√

16

Rings

4 pcs

√

17

Toolbox

1 pcs

√

18

Commissioning tools

1 set

√

Note: Commissioning tools include open spanner, internal& external pilers, cross screwdriver, slotted screwdriver, adjustable spanner ,hexagon wrench, common bolt gasket, etc.