- Email : kinsda@kinsda.cn

- Phone : +86 755 61808681

- Fax : +86 755 61808682

- Address : No.18, High-tech Industry Park, Longgang District, Shenzhen, China

-

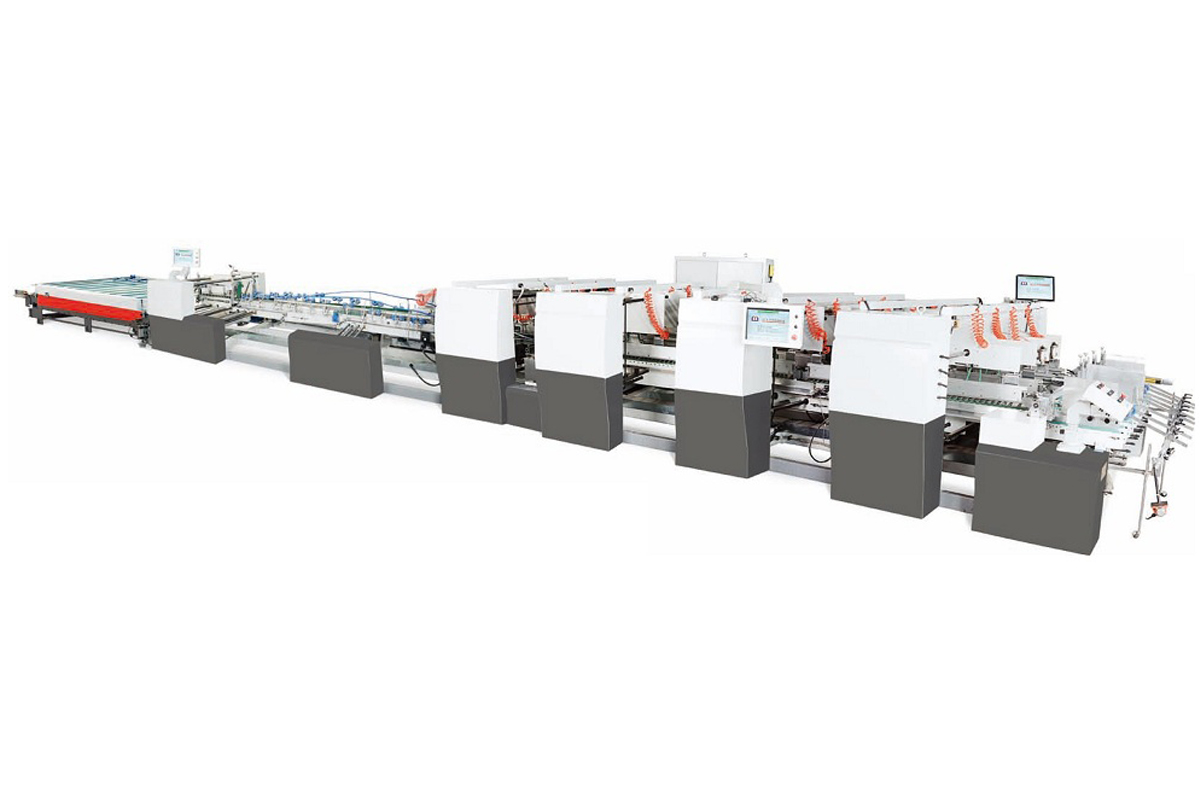

KFGD-2000/2400/2800/3200 High Speed Automatic Two Pieces Folder Gluer Machine

-

Product Description

Features:

1. Feeder Section:

◆Untimed independent and motorized with 12 sponge feeding belt with 60mm width.

◆Four lateral feed gates to adjust the width of each carton.

◆4 adjustable front feed knives, adjusting length due to each sample.

◆Squaring device can feed one or two pieces into the lateral register.

2. Two Pieces Assembly Station:

◆Five big & two small guide plates (totally 7PCS), each one big of them can adjust the distance via remote control, and the small guide plates at both sides with manual adjustment in order to keep in line with two pieces of cartons.

◆Pneumatic lateral squaring device in both sides to join two pieces after applying the glue.

◆Two sets of 4 belts with 2 or 4 logs to maximize the production as per customer’s needs.

◆Photocell sends a signal to squaring to activate the pneumatic cylinders that join the two boards.

3. Crash Lock Bottom Section:

◆4 sets of folding fingers and accessories to fold the flaps and panels of boxes.

4. Gluing Section:

◆Two lower gluing drums, left and right hand.

◆Two upper electronic gluing systems allow to glue by hot melt or cold glue, as per customer’s needs.

5. Trombone Section:

◆Upper & lower arms adjustable in length.

◆Automatic belt tensioning adjusting system.

◆Automatic box collecting mechanism to ensure boxes enter to the press section neat and well aligned to form the perfect shingle of the cartons on the collecting area.

◆Electronic counter and pneumatic kicker for counting the number of batches.

◆Squaring device for accurate closing of lock-bottom boxes.

6. Press Section (Delivery Section):

◆Independent and motorized section allow to adjust speed on conveyor.

◆Automatic mode (percentage of machine speed) manual mode (continuous operation).

◆Infeed mouth fully adjustable for snack delivery.

◆6.5m length press section with 4.7m effective pressure length.

◆Upper section moves back and forward, allowing for different box lengths.

Applications:

KFGD-2000/2400/2800/3200 High Speed Automatic Folder Gluer is a two-piece join folder gluer. It is suitable for large corrugated boxes. It is easy to set-up and friendly to operate. It can either process one or two pieces of carton. Equipped with independently motorized feeder, can feed two pieces of carton at same time and join them accurately thanks to a pneumatic lateral squaring device. The machine comes with two lower gluing wheels, left & right side, two upper electronic gluing systems, one for hot melt application and one gun and the other one for cold glue with 3 guns.

Technical Specification:

Model

KFGD-2000

KFGD-2400

KFGD-2800

KFGD-3200

Material

Carton Board Max. 1200gsm; Corrugated Flute E / C / B / AB, 3 & 5 layers

Max. Paperboard Size

1300×1800mm

1300×2000mm

1400×2800mm

1600×3200mm

Folding and Gluing Speed

200m/min

Inching Speed

10m/min

Thickness of Folded Box

Max. 20mm

Blank Width

560~1550mm/piece

Compressed Air

6 Bar

Air Compressor Capacity

30m3/hour

Air Tank Capacity

60~80L

Total Power

22.5kw

22.5kw

22.5kw

25kw

Weight

11500kg

13500kg

14500kg

15500kg

Installation Area

2800×19000mm

3200×19000mm

3600×19000mm

4000×19000mm