- Email : kinsda@kinsda.cn

- Phone : +86 755 61808681

- Fax : +86 755 61808682

- Address : No.18, High-tech Industry Park, Longgang District, Shenzhen, China

-

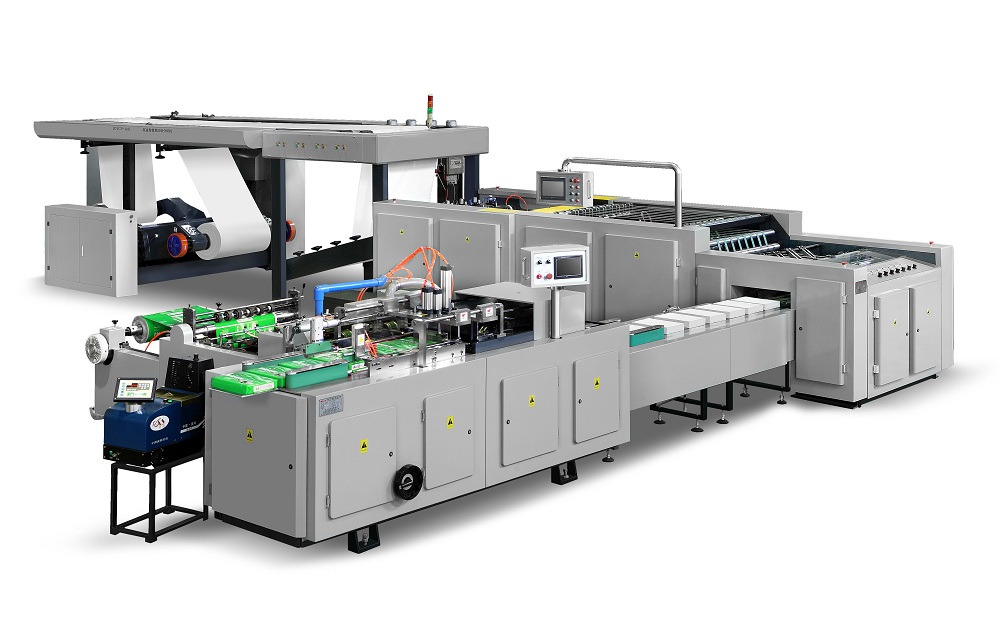

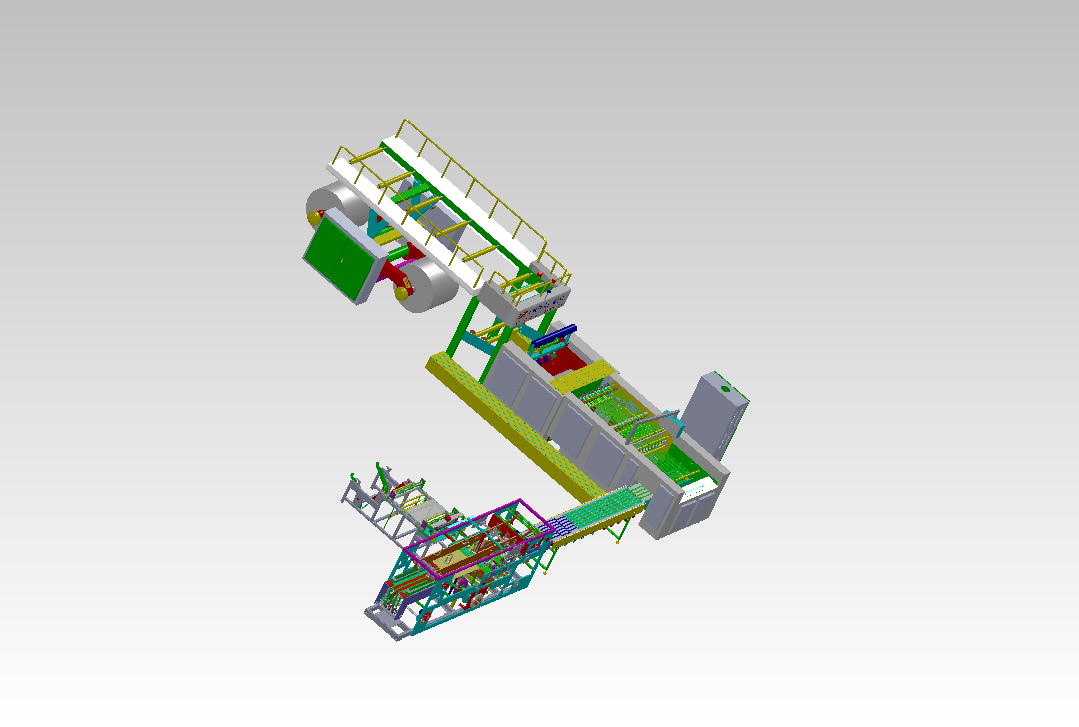

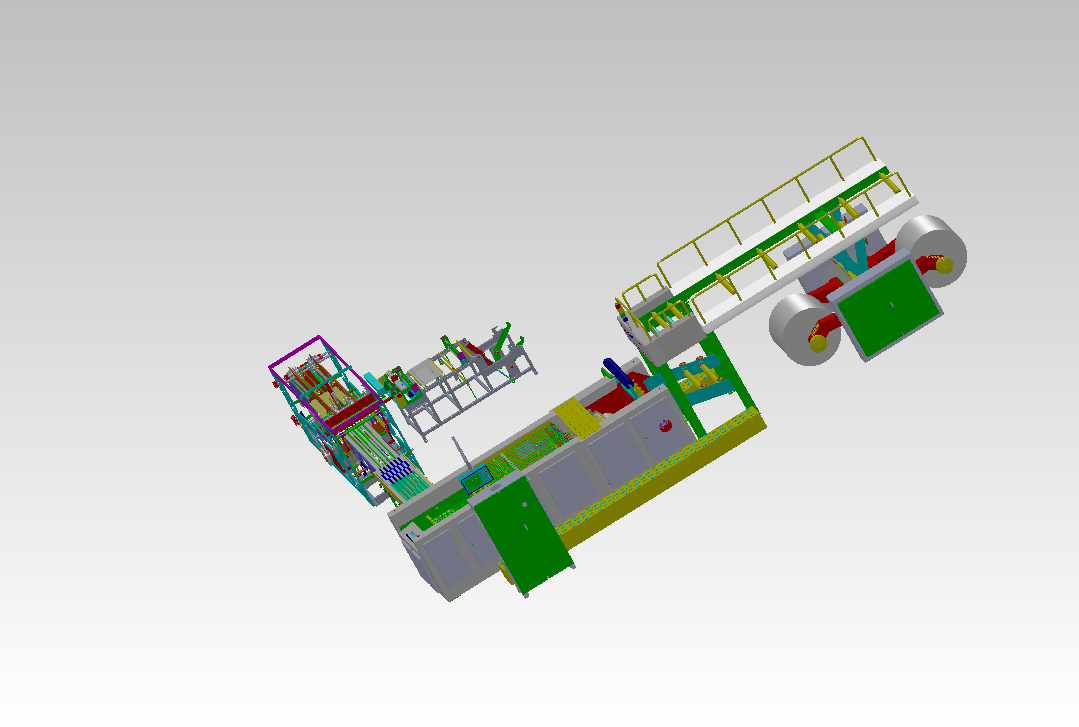

KSCPA4-2 Paper Sheeting & Wrapping Machine

-

Product Description

KSCPA4-2 Paper Sheeting & Wrapping Machine

(Size: 8.5X11”)

1. Paper sheeting(in line)

Main Structure:

1. Non-shaft paper rising shelves of the ground controlling system------ Two sets

2. Advanced tension controlling system ------ Four sets.

3.Four sets of anti-warping mechanisms------Four sets.

4. Longitudinal cutting knife groups------six sets.

5. Simultaneous cross-cutting knife groups-----One set.

6. High-speed paper feeding system----- One sets

7. Low-speed paper feeding system----- One sets

8. Waste paper automatically discharging system-----One set.

9. Making papers in order of 2D oscillation, srew rod lifting device of paper reams collecting system------One set.

10. PLC reams of paper counting device------One set.

11. Paper reams longitudinally and transverse discharging equipment-----One set.

12. PLC error alarm machine haulting system and PLC controlling equipment ------One set.

Main Technical Parameter:

Gross width

883.6mm

Net width

863.6mm

Number of cutting

2 rolls 4 slittings-A4 215.9mm(width)

Diameter of paper roll

400-1200mm

Diameter of paper roll's core

3”(76.2mm)-6”(152.4mm)

Paper grade

High grade copy paper,writing paper, two-side offset paper etc.

Weight of paper sheet

60-100g/㎡

Length of paper cutting

A4(279.4mm)

Paper quantity

0-500pages

Ream height

65mm(Max)

Designing speed of paper cutting

160m/min

Times of cutting

538/min

Cycle time of ream exhausted

4.3/min

Production speed of paper cutting

130m/min

Times of cutting

437/min

Cycle time of ream exhausted

4 Cycles/min(8-10 reams/min)

Load of paper cutting

(max)400g/㎡(4×100g/㎡)

Paper cutting accuracy

±0.2mm(Permissible error)

Paper cutting condition

1. Speed not change 2.Paper roll with no breakage 3. Qulified paper rolls.

Transmission

AC Frequency conversion,stepless speed regulating

Main power source

3phase/4line/380v/50Hz

Adjustable voltage

220V AC/22V DC

Installed capacity

22KW

Air consumption

300NL/min

Pneumatic pressure

(Min)0.6mpa---(Max)0.8mpa

Overall dimension(cutting machine)

16000×2750×2100mm

Overall Weight

14T

Configurations:

NO.

NAME

QTY

ORIGIN

MODEL

1

Pneumatic round knife

5 sets

Italy DELSAR

——

2

Down round knife

5 sets

German LUXEMBURG

——

3

Sheeting blade

4 pcs

German LUXEMBURG

1100×30(mm)、1100×35(mm)

4

Key Bears

1 set

German FAG

——

5

Timing Belt

1 set

German EHRE

——

6

Conveying Belt

1 set

Switzerland RAPPLON

——

7

PLC

1

German SIMENS

S7-200/224

8

PLC Modular

1

German SIMENS

S7-200/223(16 input 16 output)

9

PLC Modular

1

German SIMENS

S7-200/223(4 input 4 output)

10

PLC Modular

4

German SIMENS

S7-200/223(4 input 4 output)

11

Relay

24

Japan OMRON

MY2N-J/PYF08A-E

12

Contactor

1

German Schneider

LCE1-3210

13

Contactor

2

German Schneider

LCE1-1810

14

Contactor

4

German Schneider

LCE1-0901

15

proximity

2

Japan OMRON

E2E-X5ME1-Z

16

Photoelectrical Switch (round)

5

Japan OMRON

E3FA-DN11

17

Small U shape photoelectrical Switch

1

Japan OMRON

EE-SX670A/E53D

18

Contactor

3

German Schneider

LCE1-1810

19

Contactor

10

German Schneider

LCE1-0901

20

Relay

30

Japan OMRON

MY2N-J/PYF08A-E

21

Frequency Convertor

1

Japan YASKAWA

A1000

22

Touch Screen

1

Taiwan WEINVIEW

MT6100I

23

Servo Motor

1

China HUICHUAN

0.2KW

24

Servo Driver

1

China HUICHUAN

IS500PS5R51-114

25

Gear Motor (1:50)

1

CHINA

0.4KW

26

Gear Motor (1:50)

1

CHINA CHENGPANG

0.4KW

27

Gear Motor (1:10)

1

CHINA CHENGPANG

0.4KW

28

Gear Motor (1:25)

1

CHINA

0.4KW

29

3-phase asynchronous motor

1

CHINA

15KW

30

3-phase asynchronous motor

3

China KUAYUE

2.2KW Y100L1-4

31

3-phase asynchronous motor

5

China

0.18W YS6324

32

Frequency Converter

4

China HUICHUAN

MD210T1.5B

33

Wallboard of Sheeting Unit

2 pcs

CHINA

Nodular Cast Iron

34

Wallboard of unwinding Unit

4 pcs

CHINA

Nodular Cast Iron

35

Hydraulic System

2 sets

China

——

36

Anti-static

2 sets

China

——

2. Wrapping machine (in line)

Main Technical Parameter:

Productive capacity

8-10 reams/min

Function of roll overwrap paper

can be automatically cross cut and fed

8-10 sheets/min

Specification of packed object

215.9×279.4×50mm (Based on the height 500 pieces of copying paper.)

Wrapping Material

Roll laminated paper

Sealing Method

Hot melt glue

Power supply

380V/3Phase/4Wire

Motor power

5.1kw

Rubber roller power

2.25kw

Compressed air

0.6-0.8 mpa

Paper size(Lenght×Width)

550-560mm×386mm

Overall dimension

4530×3050×1450mm

Weight

2.5T

Configurations

NO.

NAME

QTY

ORIGIN

MODEL

1

PLC

1

SIMENS

S7-200/224

2

PLC MODULAR

1

SIMENS

(16 INPUT 16 OUTPUT)

3

APPROXITY SWITCH

2

OMRAN

E2E-X5ME1-Z

4

SQUARE APPROXITY SWITCH

1

OMRAN

TL-05MC1-Z

5

Small U Photoelectric Switch

11

OMRAN

EE-SX670A/E53D

6

U Photoelectric Switch

1

OMRAN

SU-07R

7

Photoelectric Switch (round)

2

OMRAN

E3FA-DN11

8

Optic Fiber

1

OMRAN

E32-ZD200

9

1

OMRAN

E3X-ZD11

10

RELAY

16

OMRAN

MY2N-J/PYF08A-E

11

CONTACTOR

3

SCHNEIDER

LCE1-1810

12

CONTACTOR

1

SCHNEIDER

LCE1-0910

13

Color Senser

1

CHINA

GREEN LIGHT

14

PHOTOELECTRIC SWITCH (METAL ROUND)

1

RUIXIANG,CHINA

E12-DS10C1

15

SERVO MOTOR

1

HUICHUAN,CHINA

1KW

16

SERVOR MOTOR

1

HUICHUAN,CHIAN

IS500AS7R61-112

17

)

REDUCER MOTOR

1

LICHAO,CHINA

0.4KW

18

SINGLE PHASE REDUCER MOTOR

2

CHINA

5IK120RGU-CF-5

19

STEP MOTOR

1

BAOMA QIANYANG,CHINA

20

STEP MOTOR DRIVER

1

LEISAI,CHINA

3ND2283-600

21

3 PHASE ASYNCHRONOUS MOTOR (2 ENDS AXIS)

1

LICHAO,CHINA

4.0KW

22

FREQUENCY CONVERTOR

1

HUICHUAN,CHINA

MD280N73.7GB/5.5PB

23

3 PHASE ASYNCHRONOUS REDUCER MOTOR

1

CHENGBANG,CHINA

0.2KW

24

FREQUENCY CONVERTOR

1

HUICHUAN,CHINA

MD210T1.5B

25

AXIAL FLOW FAN

1

FULI,CHINA

HG-1500B(1.5KW)

26

AXIAL FLOW FAN

1

FULI,CHINA

HG-2200B(2.2KW)

27

TENSION CONTROLING PLATE

1

HUAGUANG,CHINA

SZK-C3

28

MAGNETIC POWDER BRAKE

1

HUAGUANG,CHINA

FZ100S

29

Hot-melt Glue Spraying Machine

1

HUANGSHANG,CHINA

HS8100P(3 GUNS)

30

TOUCH SCREEN

1

WEINVIEW,TAIWAN

TK6070IH